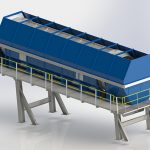

MATERIAL RECOVERY FACILITY EQUIPMENT

After the manual pre-sorting process, garbage is screened by a trommel screen, and to maximizing extraction of different kinds of recyclable material, partially by NIR technology, it can be sorted by color or by material, and then separated recyclables will be processed by solid waste baler machine for transport.

To provide recyclable garbage more value, it is received and sorted using the Hengchuang material recovery facility equipment (Clean MRF sorting equipment) technology from solid waste management equipment manufacturer. According to the physical characteristics of the waste, clean MRF separates polymers (often PET and HDPE), ferrous and non-ferrous metals, paper, glass, etc.

PET bottles can also be produced from used PET bottles, depending on the purity of the recycled PET bottles. PET bottles may be produced from used PET bottles, depending on the quality of the recycled PET flakes. By adding virgin grade plastic resin to low purity recycled plastic, we may create high quality plastic items.

Clean MRF Sorting Equipment Functions

Material Recovery Facilities (MRFs) use a variety of MRF sorting equipment to process and separate recyclable materials. Some common types of clean MRF sorting equipment include:

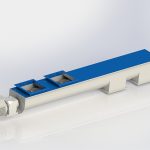

MRF Conveyor belt: waste sorting conveyor belts is used to transport materials through the MRF. They may be equipped with sensors or other technologies to help identify and sort different types of materials.

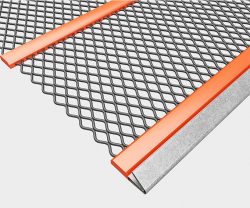

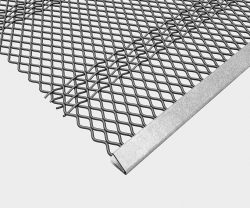

Trommel screens: Wholesale Trommel screen is cylindrical screens that rotate to separate materials based on size and density. They are often used to remove larger contaminants from the recycling stream.

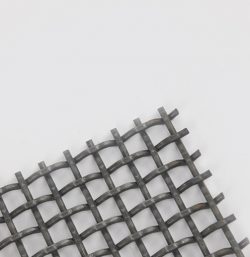

Air classifiers: Air classifiers use air streams to separate materials based on their weight and density. They can be used to separate materials such as paper from heavier materials like plastic bottles.

Eddy current separators: Eddy current separator machine use magnetism to separate non-ferrous metals (such as aluminum) from other materials.

Optical sorters: optical sorter recycling use cameras and other sensors to identify and sort materials based on their physical characteristics, such as color and shape.

Magnetic separators: Magnetic separator machine use magnetism to separate ferrous metals (such as steel) from other materials.

The specific MRF sorting equipment used in an MRF will depend on the types of materials being processed and the desired end products.

Clean MRF Material Recovery Facility Equipment Advantages

Material Recovery Facilities (MRFs) are facilities that are designed to sort, process, and store recyclable materials. There are several advantages to using clean MRF sorting equipment:

Increased efficiency: clean MRF sorting equipment is specifically designed to efficiently sort and process recyclable materials, which can help to increase the overall efficiency of the facility.

Enhanced separation: clean MRF sorting equipment can effectively separate different types of recyclable materials, ensuring that they are properly sorted and stored for later processing.

Reduced contamination: By accurately sorting materials, clan MRF sorting equipment can help to reduce the contamination of recyclables, which can improve the quality of the materials and increase their value.

Cost savings: clean MRF sorting equipment can help to reduce labor costs, as the clean MRF sorting equipment can handle much of the sorting and processing tasks that would otherwise be performed manually.

Environmental benefits: Using clean MRF sorting equipment can help to reduce the amount of waste that is sent to landfills, as more materials can be recycled and repurposed. This can help to reduce the negative environmental impacts of waste disposal.

https://www.hcmswrecycling.com/mrf-material-recovery-facility-equipment.html