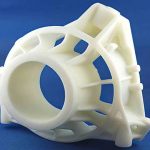

What is Vacuum Casting?

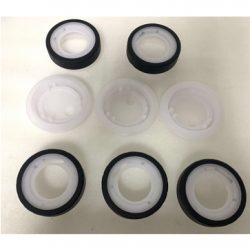

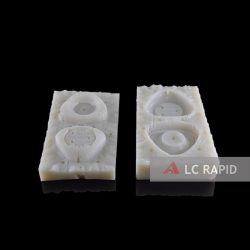

Vacuum casting is also called urethane casting. It is a copy technique formed by silicone mold to produce a small batch of functional parts. It is a great way to get parts with good surface detail and fidelity to the original pattern. Vacuum Casting is well known for its speedy and stable production way for prototyping manufacturing.

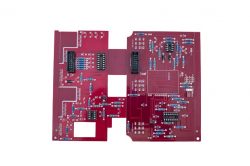

At Xin Pin, we will offer you a complete solution for accelerating your project development based on your CAD design. We can create parts for engineering functional sample parts, qualified display models, and more.

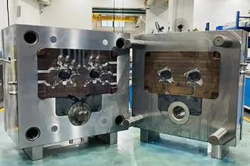

Specification of Vacuum Casting

Standard Lead Time

Up to 15 copies within 10 working days.

Standard Accuracy

Standard tolerance on±0.15mm/100mm.

Minimum Wall Thickness

To ensure that the mold is filled properly, minimum at least 0.75mm. But we recommend a wall thickness of at least 1.5mm.

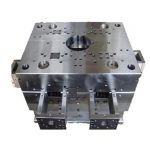

Maximum Part Dimensions

The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters).

Typical Quantities

Up to 25 copies per mold (depending on the mold’s complexity and the casting materials).

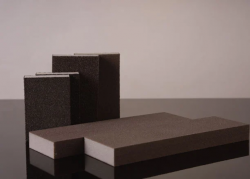

Surface Structure

High-quality surface finishes comparable to injection moldings, such as Electroplating, Spraying, etc.