CNC Machining Aluminum

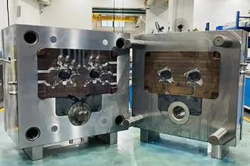

We produce almost any form of product for our customers. Our company provides CNC machining services of high precision aluminum machined parts. We CNC machine, cnc lathe all sorts of aluminum alloys. Furthermore, YS Rapid will be glad to assist you in optimizing your parts in order to reduce production costs or improve the technical characteristics of your products during the development process.

Advantages of Aluminum Alloy in CNC Machining

In the field of CNC precision mechanical parts processing, because of the material characteristics of aluminum, aluminum parts are widely used in many fields, so aluminum parts are very common parts.

CNC machining Aluminum Characteristics and Advantages:

1. The hardness of the material is moderate, and the tool wear of the processing equipment and CNC machining center is small.

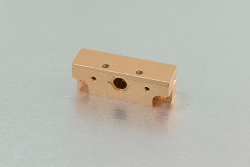

2. It can be precisely processed into various geometric shapes such as planes, cavities, shells, spheres, arcs, and heterosexuality.

3. Not easy to get dirty, easy to maintain and clean.

4. It has good durability and is not easy to corrode, and the special surface treatment process makes the service life of the parts longer.

5. Aluminum material is environmentally friendly, can be recycled, and has a high recycling value

The above five points are the material advantages of aluminum machined parts. Aluminum is a common material in CNC precision parts machining. Its material has moderate hardness, durability and is not easy to corrode. In addition, the cost of the material itself is not high. It is the preferred material for most machined parts manufacturers.

What are the Common Surface Treatment processes for Aluminum CNC Machining Parts?

Before the surface treatment of aluminum products, aluminum materials generally need to be pre-treated: degreasing→rust removal→cleaning→phosphating or purification, etc. Most of the workpieces with rust or thick surface are derusted by mechanical methods such as sandblasting and shot blasting, but the surface of the workpiece should be clean and free of dirt after mechanical derusting.

1. Polishing. Polishing removes surface defects and burrs, etc., making the surface bright and smooth. Polishing can be divided into chemical polishing and mechanical polishing

2. Sandblasting: The purpose of sandblasting is to solve and cover up some defects of aluminum alloy during machining and to meet some special requirements of customers for product appearance. There are glass sand, tungsten sand, etc., showing different feelings, similar to the rough texture of frosted glass, and fine sand molds can also show high-end products.

3. Metal plating. It is more common, and there is a treatment process of electroplating after polishing.

4. Lathe pattern: aluminum surface treatment is the treatment method of reprocessing after the mold is formed. Using a lathe to process the pattern, the finished product shows a very regular texture feature.

5. Brushed Finishes: The performance is similar to that of the car pattern, which forms smooth continuous lines on the surface. The difference is that the car pattern appears as a ring pattern, and the brush finishes appear as a straight line.

6. Oxidation and Anodizing (coloring): The use of aluminum surface treatment oxidation is divided into two aspects, enhancing the physical properties and achieving the purpose of coloring. Generally, it is anodized. The purpose is to color, and the second is to increase the surface hardness and improve wear resistance, such as micro-arc oxidation.

7. Passivation: A method of turning the metal surface into a state that is not easily oxidized, thereby delaying the corrosion rate of the metal.

8. Painting: Paint a layer of coating on the surface of aluminum, you can paint white, paint yellow, paint blue, spray wood grain, etc.

YS Rapid – Professional CNC Machining Aluminum Parts Manufacturer in China

As a professional metal CNC machining manufacturer, YS Rapid has professional technicians and management teams to customize machining your design drawings. We have more than ten years of rich experience and knows the characteristics of each kinds of aluminum alloy. So we can provide the best aluminum machining method for your aluminum parts and products.

Why Choose Our Aluminum CNC Machining Services?

Capable of processing a wide variety of machining aluminum materials, such as:

Aluminum 6061, 2024, 5052, 6063, 7050, 7075

We can provide a variety of surface treatments for aluminum cnc machined parts, including:

Sand blasting, polishing, clear anodizing, color anodizing, oxidation, electrophoresis, chromating, powder coating, painting, silk screen printing, electroplating, and so on.

We provide all kinds of aluminum CNC precision machining:

Aluminum CNC Milling, Aluminum CNC Lathing, Aluminum CNC Drilling, etc.

No minimum order, we accept single aluminum part machining, to small volume and high volume aluminum parts machining. No matter big order or small order, we will provide all the best quality and best service.

Fast response. Your inquiry for prices or questions about our machining services will be replied within 24 hours .

Properties of the Most Common Aluminum Materials Used in CNC Machining

Aluminum 6061 – It is commonly used in CNC milling machines. It is an inexpensive material with good mechanical properties and easy welding. The hardness of this aluminum alloy ranges from medium to high. Aluminum 6061 is easy to do anodizing and bending.

Aluminum 7075 – This alloy has good impact resistance, but its properties make it unsuitable for welding. In addition, this material is high corrosion resistant. Aluminum 7075 is a very commonly used metal material in the manufacturing parts of bicycle and wheelchair.

Aluminum 2024 – This material is widely used in the fields of aerospace and defense. 2024 aluminum alloy maintains excellent wear resistance and high corrosion resistance in harsh environments. However, it is also considered one of the most difficult materials to weld.

We strongly recommend that you choose the right aluminum material for your machined components. If you need help, please feel free to contact us. Our years of rich experience in aluminum alloy CNC machining will be helpful to your aluminum parts customization.