Vacuum Casting Service

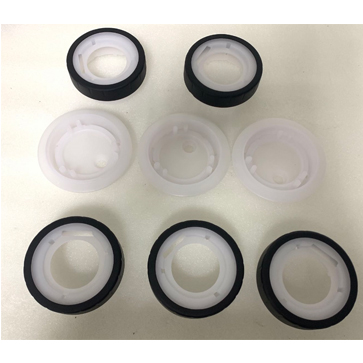

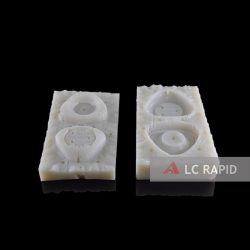

Vacuum casting service is to make use of the 3D printing SLA or CNC model sample, like the vacuum casting metal. Vacuum casting factory Proto-mold will do the silica gel mold in the vacuum state situation, and then we will pouring by the PU resin materials so that vacuum casting company can copy the same parts from the vacuum casting silicone mold.

Vacuum Mold Casting Process

Vacuum casting process is a process used to create hollow objects. Many parts of the world are beginning to use die casting vacuum system because it is cheaper than other methods, such as sand casting and investment casting.

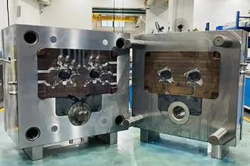

In order to understand how vacuum casting method works, it’s important to know what a mold looks like. For vacuum casting manufacturers, a mold is made by pouring molten metal into a carved piece of stone or metal that has been carved into the shape needed for your object. The molten metal will take on the exact same shape as your carved piece when it cools down and hardens in place.

The vacuum casting process consists of the following steps:

Molding

Flashing and trimming

Venting and degassing (optional)

Cooling (optional)

Release agent application (optional)

Sealing the mold and degassing again if necessary (optional)

Casting materials such as silicon rubber are applied over a surface that has been coated with release agents to allow for easy removal of the finished product after it has cured.

Common Vacuum Casting Applications

Vacuum casting service is a versatile process that is often used to form metal parts and products in industries such as aerospace and automotive. Vacuum casting service can also be used in other applications where a need for large numbers of complex parts, small detail, or both exists. For example, vacuum casting suppliers can produce small intricate details on components that may be larger than their traditional counterparts. This allows vacuum casting manufacturers to produce complex shapes without fear of warping or bending under pressure when they’re assembled into finished products. You can use vacuum casting for a variety of applications. Among the most common are:

Automobile parts. Vacuum casting service is used to make automotive parts such as brake calipers, suspension parts and engine covers.

Medical devices. Vacuum casting service is used to create medical devices such as surgical pins, dental implants and nasal stents.

Vacuum casting service has become very popular due to its ability to create high-quality production runs at low cost while using less energy than traditional steel-forming processes like machining or stamping (it’s much faster too!). As such, it’s become the preferred method for creating certain types of vacuum casting metal products like pipes which require precise tolerances; this method will eliminate costly downtime from manufacturing because there’s no need for rework once the pieces are casted properly before assembly takes place.