FOUR SIMPLE INJECTION MOLDING METHODS

Date: Apr 01 2020 | By:LC Rapid

Tag:Plastic Injection Molding,

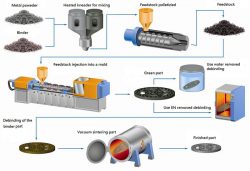

Some factors of a part, whether material, rough, cycle time, or more, greatly affect their price. there are four tips for lowering part prices without sacrificing the components you need for success.

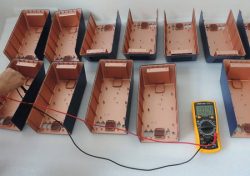

1.Material

By knowing what the best injection molding materials for parts is, you can improve economic efficiency. The first factor in deciding which material to use is where your parts will live. Will it be outdoors, indoors, next to the oven? The durability, temperature and stability need of the parts will help meet the material what you real need. Professional Tip: A quick way to determine materials is to look at the materials of existing products running in a similar environment – no need to reinvent the wheels.

The price of the material per pound/KG will vary greatly depending on the characteristics and advantages. For example, HDPE (high density polyethylene) costs about $1.50 per pound, while materials like polysulfone cost $12-15 per pound. When you can use cheaper materials without sacrificing parts needs, you can save money by choosing the most cost-effective option.

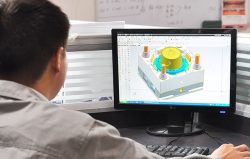

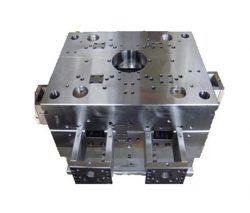

2. Cycle time

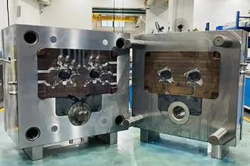

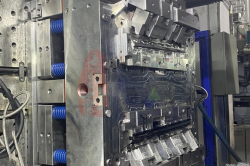

The faster the cycle time, the less overhead each part will be. The cycle time is the time it takes for the part to form during molding. The cycle time depends on the mold build, the water circuit, and its ability to cool the plastic to solid state.

https://www.lcrapid.com/four-simple-injection-molding-methods.html