CNC Swiss Machining

CNC Swiss Machining

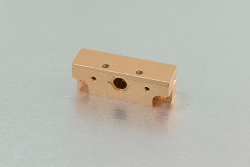

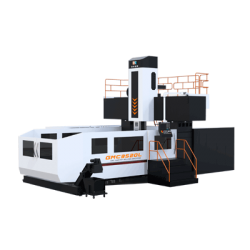

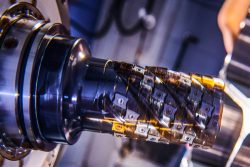

CNC Swiss machining is a specialized type of precision machining that involves the use of a sliding headstock lathe to produce intricate parts with high accuracy and tight tolerances. This process is particularly well-suited for small, complex parts that require multiple operations to be performed in a single pass. CNC Swiss machining is known for its ability to produce parts with very tight tolerances, high surface finishes, and excellent straightness, roundness, and concentricity. Falcon’s Swiss machining technology is widely used in industries such as medical, aerospace, optics, and electronics, machine & equipment, automotive precision machining, where precision and quality are of utmost importance.

What Are the Advantages of CNC Swiss Precision Machining?

High precision and accuracy: CNC Swiss machining equipment uses advanced technology and specialized tools that allow for very tight tolerances, resulting in parts with exceptional precision and accuracy.

Consistency and repeatability: Highly automated lathe, ensuring consistency and repeatability in the manufacturing process, which is critical for high quantities production.

Multi-axis machining: The Swiss lathe has multiple axes that allow for complex geometries and shapes, which is essential for producing intricate parts and components.

Reduced lead time: CNC Swiss turning machining is known for its high efficiency and fast production times, resulting in reduced lead times and faster delivery of parts and components.

Versatility: It can work with a wide range of machining materials, including metals, plastics, and composites, making it ideal for various industries such as aerospace, medical, and automotive.

Cost-effective: CNC Swiss machining is a cost-effective solution for high-volume production runs, as the high level of automation reduces labor costs and minimizes waste.

Why Is It Called Swiss Machine?

The term “Swiss machine” typically refers to a type of precision lathe called a Swiss-type lathe, also known as a Swiss screw machine. This type of lathe was originally developed in Switzerland in the late 19th century for the watchmaking industry, which required very precise and complex parts to be produced in large quantities.