CNC Machining ABS

Machining ABS material is an abbreviation for acrylonitrile-butadiene-styrene copolymer board, and is a type of polymer board that combines the excellent abrasion resistance, oil resistance, and impact resistance of PS, SAN, and BS boards. A new type of material in the fields of food industry parts, building models, refrigerator refrigeration industry.

Advantages of CNC Machining ABS

1. CNC Machining ABS is very hard, so they have strong impact resistance, scratch resistance, stable size and other characteristics, and at the same time have the characteristics of moisture resistance, corrosion resistance and easy processing.

2. CNC Machining ABS also has good light transmission and toughness.

3. CNC Machining ABS material is also very environmentally friendly. Because it is a kind of plastic machining materials that uses environmentally friendly chemical substances, it is non-toxic and odorless, and it can also be insulated from electricity. It is a very safe material.

4. CNC Machining ABS material is easy to deform in an environment with too high temperature, and its deformation temperature is 93-118°C, but it has good performance in a low temperature environment of -40°C, so it is also a material that is afraid of high temperatures.

Five Application Industries of CNC Machining ABS

CNC machined ABS has strong impact resistance, scratch resistance, dimensional stability and other characteristics, and at the same time has the characteristics of moisture resistance, corrosion resistance and easy processing, so it can replace a large number of metal materials. ABS machined products are widely used in home appliance appliances, electronic appliances, automotive, mechanical equipment, office equipment and other industries.

1. Home appliance industry

CNC machined ABS is widely used in home appliances, including TVs, radios, washing machines, hair dryers, microwave ovens, refrigerators, telephones, air conditioners and other shells and internal components.

2. Electronic appliances industry

ABS is widely used in the production of various electrical products, electronic product casings, electric meter covers and casings, household switches, plugs and sockets, cable and wire conduits.

3. Automotive industry

CNC ABS has excellent impact resistance, strength, stiffness, and ease of processing, etc., and is widely used in the production of many auto parts. Such as shells, handles, control switch knobs, fenders, armrests, etc.

4. Mechanical equipment industry

CNC machining ABS can produce mechanical equipment and general mechanical parts. Such as water tanks, housings, electrical cabinets, battery tanks, gear bearings, pump impeller mold models and fasteners, bolts, cover plates, etc.

5. Office equipment industry

Due to the excellent impact resistance and rigidity of ABS, dimensional stability and formability, moreover, it is also economical and practical, making it an ideal material for manufacturing various office equipment casings. Such as the production of office equipment such as fax machines, copiers, typewriters and computer monitors. If there is a flame retardant requirement, flame retardant ABS is generally used.

Properties and Usage of of Modified ABS Materials:

Flame retardant ABS:

Flame-retardant ABS material has excellent flame retardancy and good processability, meets environmental protection ROHS and REACH requirements, and has passed UL yellow card certification. It is mainly used in home appliances, OA equipment, routers, low-voltage electrical appliances, etc. Typical grades are FRABS410, FRABS412, FRHIPS410, HIPS412.

Heat-resistant ABS:

Heat-resistant ABS material has high heat resistance, balance of rigidity and toughness, and excellent spraying and electroplating properties. It is mainly used in microwave oven frames, hair dryer casings, car air-conditioning outlets, and heat dissipation grills. Typical grades are ABS810A, ABS810B, ABS810C and so on.

High-gloss ABS:

High-gloss ABS material has the characteristics of high gloss, good processability and scratch resistance, and is mainly used in TV frame, washing machine and air conditioner panel, etc. Typical grades are HA1020, HA3020, etc.

High-gloss spray-free ABS:

High-gloss spray-free ABS material has metallic luster and good processability, and is mainly used in panels of rice cookers, washing machines and air conditioners. Typical grades are MA1020 and MA2020.

Enhanced ABS:

Reinforced ABS material has the characteristics of high strength, low shrinkage, and high dynamic balance. It is mainly used in air-conditioning axial flow and cross-flow fans, electrical frameworks, etc. Typical grades are ABSG210 and ABSG310.

Food grade ABS:

Food-grade ABS material has the characteristics of good toughness and food hygiene and environmental protection grade (FDALFGB). It is mainly used in the upper cover, cup body and lower cover of juicer and cooking machine. Typical grades are ABS810-LFGB and so on.

Alloy PC/ABS:

Alloy PC/ABS material has the characteristics of high toughness, stress crack resistance, heat resistance, and high weld line strength. It is mainly used in mobile phone casings, computer notebook casings, and home appliance casings. Typical grades are PC/ABSH073, PC/ABSH 073H, P2020, P2016.

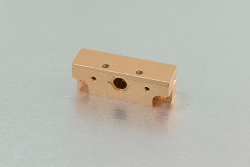

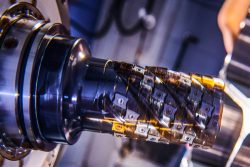

YS Rapid’s CNC Machining in ABS Materials – Precision ABS CNC Machining Parts Manufacturer

Our company is one of the professional precision machining suppliers in China. With over ten years of experience in machining high-quality CNC machining precision parts, we are dedicated to machining parts from various CNC machined materials, including one of the most commonly seen plastics – Machining ABS plastic material. We custom CNC machine precision CNC ABS parts according to customers’ drawings. YS Rapid offers full range of plastic ABS machining services including CNC milling ABS and CNC lathing ABS to manufacture abs parts in various shapes and sizes. In addition, we can also carry out various surface treatments for CNC machining ABS precision parts, such as painting, silk screen printing, electroplating, etc. Our precision CNC ABS parts are widely used in electronic products, automobiles, medical instruments, home appliances and other industries.