DOUBLE-PALLET HORIZONTAL MACHINING CENTER

This high-precision horizontal machining center was designed and produced by our company on the basis of introducing and absorbing advanced technology at home and abroad. It is a four-axis three-linkage CNC machine tool controlled by a CNC system. High precision, high speed, high efficiency, and high reliability are the main features.

FEATURES OF DOUBLE-PALLET HORIZONTAL MACHINING CENTER

The machine bed is integrally cast with nano-polymer mineral composite material, which has excellent vibration absorption and thermal stability, which can effectively improve the surface processing quality of the workpiece and the service life of the tool.

The mineral casting used in the equipment has strong shock absorption, and its vibration frequency is 10 times lower than that of cast irons. Under a large dynamic load, the stability of the accuracy of the machine tool is ensured, and the surface processing quality of the workpiece is increased by 20%.

The thermal conductivity is 1/20 of cast iron, and the specific heat capacity is 2.1 times that of cast iron. The deformation of the machine tool caused by temperature changes is effectively controlled, and the stability of the machining accuracy of the machine tool is ensured.

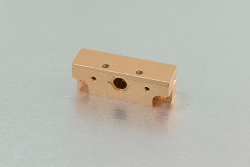

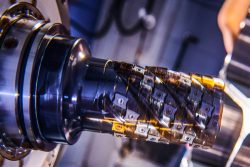

After the workpiece is clamped on the machining center once, the digital control system can control the machine tool to automatically select and change tools according to different processing procedures, automatically change the spindle speed, feed speed, and the motion path of the tool relative to the workpiece and other auxiliary functions. Complete multi-process processing on multiple surfaces of the workpiece. And there is a variety of tool change or tool selection functions so that the production efficiency is greatly improved.