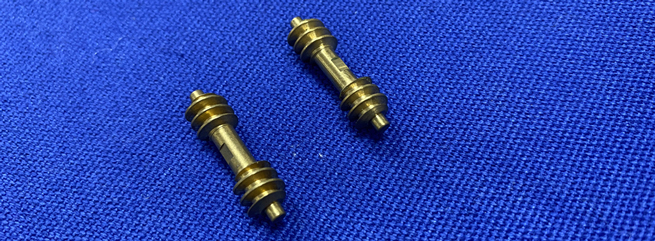

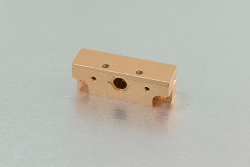

Brass and Copper Precision Machining

Is Brass Easier to Machine than Copper?

Copper is a soft, malleable metal that is an excellent conductor of electricity and heat, which makes it suitable for use in a wide range of industries, including electronics, aerospace, and automotive.

Brass is an alloy of copper and zinc, and it is often used in Swiss machining because it is relatively easy to machine and has good corrosion resistance. Brass is generally easier to machine than copper in Swiss machining due to its lower hardness and better machinability characteristics.

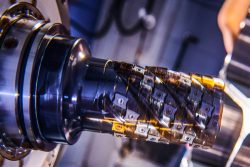

In Swiss machining, both brass and copper can be turned, drilled, and milled to create complex shapes and features with high precision. The choice of material will depend on the specific requirements of the part being produced, as well as factors such as cost, availability, and compatibility with other components.

Benefits of Precision Swiss Machined Brass and Copper Parts

Brass and copper machining in Swiss machining offers several benefits due to the unique properties of these materials and the capabilities of the Swiss machining process. Here are some advantages of brass and copper machining in Swiss machining:

Excellent Machinability: Brass and copper are known for their excellent machinability, making them ideal for Swiss turn machining. They are softer than many other metals and can be easily shaped, formed, and machined to complex geometries with tight tolerances.

Superior Conductivity: Both brass and copper are highly conductive materials, making them suitable for electrical and thermal applications. In Swiss machining, brass and copper can be precisely machined to create connectors, terminals, electrical contacts, and heat sinks that require excellent electrical and thermal conductivity.

Corrosion Resistance: Brass and copper form protective oxide layers on their surfaces, protecting them from environmental factors and enhancing their durability. Swiss machining can produce components with precise dimensions and smooth surfaces, further improving their resistance to corrosion.

Strength and Durability: Brass and copper are inherently strong and durable materials, making them suitable for various applications. Swiss machining allows for the production of precise and robust components that can withstand high loads, vibrations, and mechanical stresses.

Aesthetic Appeal: Brass and copper have visually appealing appearances. Their warm, attractive colors and ability to be polished, plated, or finished make them desirable for applications that require an aesthetic touch, such as decorative or architectural components.

By leveraging the benefits of brass and copper machining in Swiss machining, Falcon can produce high-quality, precision components that meet stringent requirements in various industries, including automotive, electronics, aerospace, medical, and more.

Falcon Brass and Copper Machined Parts Application

Brass and copper are commonly used materials in Swiss machining due to their excellent machinability and desirable properties. It finds applications in a wide range of industries. Here are some common areas where these parts are used:

Automotive Industry: Brass and copper machined parts are used in various automotive applications, including fuel systems, engine components, electrical connectors, cooling systems, and braking systems.

Electronics and Electrical Industry: Brass and copper machined parts are widely utilized in the electronics and electrical sectors. They are used in connectors, terminals, switches, circuit boards, heat sinks, and electrical contacts. The high electrical and thermal conductivity of brass and copper makes them ideal for efficient and reliable electrical connections.