4 Axis CNC Machining

4 axis custom CNC machining service provided for the prototype manufacturing of high precision and quality mechanical parts such as sprial shaft and gear as well as complex components for both metal and plastic.

For your next 4-axis CNC milling job, team up with Fathom Precision’s creative aerospace professionals. We are a dependable prototyping company of high-performance complicated aircraft components because to our extensive superalloy expertise and understanding of the aerospace industry. For your 4-axis milling needs, get in touch with us right now.

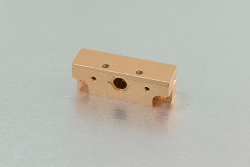

4 Axis CNC Machined Part

A 4 axis CNC machined part refers to a component that has been produced using a CNC (Computer Numerical Control) machine that has the capability to rotate around four different axes. These machines are capable of producing parts with a high degree of precision and accuracy.

4 Axis CNC Machined Part

The main feature of a 4 axis CNC machined part is its ability to be produced with a greater level of complexity and precision than other manufacturing processes. This is due to the ability of the CNC machine to rotate around four different axes, allowing for a more intricate design to be produced. Additionally, 4 axis CNC machines are often able to produce parts at a faster rate than other machines, which can make them a more cost-effective manufacturing solution.

4 Axis CNC Machined Part

4 axis CNC machined parts are used in a wide range of applications, including aerospace, automotive, medical devices, and electronics. They are often used in applications where a high degree of precision is required, such as in the production of complex shapes, intricate designs, and tight tolerances.

4 Axis CNC Machined Part

Some of the main advantages of using 4 axis CNC machining to produce parts include the ability to produce complex designs with a high degree of precision and accuracy, the ability to produce parts at a faster rate than other machines, and the ability to produce parts with a high level of consistency and repeatability. Additionally, CNC machining can often be more cost-effective than other manufacturing processes, especially for larger production runs.