CNC TAPPING MACHINE

CNC TAPPING MACHINE

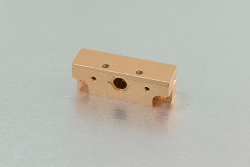

Vt series is a vertical drilling center independently designed and developed by our company. The product has the structural characteristics of high speed, high precision, high rigidity, and high reliability. It can work continuously and normally under specified environmental conditions with stable precision. The machine tool is widely used in the 3C industry, 5g, it, aviation, aerospace, auto parts, small mold processing, medical devices, and other industries, especially for high-efficiency processing of high-yield parts and non-ferrous metals.

CNC TAPPING MACHINE SPECIFICATION

VT60B

X-axis Travel

mm

1100

Y-axis Travel

mm

600

Z-axis Travel

mm

350

From spindle nose to worktable face

mm

250~600

Distance from spindle center to column

468

Worktable Size

mm

1200*600

A large load of workbench

kg

400

T-slot

mm

14H7*5*120

X/Y/Z-axis Rapid Traverse

m/min

60/60/60

Feedrate speed

X/Y/Z -axis Cutting Speed

m/min

20/20/20

acceleration

1g

Spindle type

Direct connection

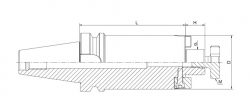

Spindle taper

BT30

Spindle speed

rpm

12000

Main motor power

KW

3.7/7.5

Spindle Torque

N.M

23.6/47.7

X/Y/Z Positioning Accuracy (half-closed loop)

mm

0.008

X/Y/Z Repeatability Accuracy (half-closed loop)

mm

0.005

ATC

Turret type

ATC Capacity

21

Larger tool size

mm

φ100/φ140/250

Larger tool weight

kg

3

Air source pressure

MPa

0.65

Power capacity

KVA

250~600

Machine size (length*width*height)

mm

2760*2600*2720

Machine weight

kg

6000